So, you’re looking to dive into the world of jewelry manufacturing and have your sights set on China? Smart move. China has become the go-to destination for businesses around the globe looking for affordable, high-quality, and scalable manufacturing solutions—especially when it comes to jewelry.

But with great opportunity comes a fair share of risk, confusion, and decision fatigue. The last thing you want is to sink thousands of dollars into a production partner who disappears, delivers subpar quality, or simply can’t keep up with your needs.

Finding a reliable jewelry manufacturer in China isn’t just about scrolling through Alibaba and picking the shiniest profile. It’s about understanding the landscape, knowing what questions to ask, verifying every claim, and setting up processes to protect your brand and your money.

This guide will walk you through every step of the journey—from understanding China’s jewelry market to closing deals and shipping your products across the globe. Whether you’re a budding entrepreneur, an established e-commerce brand, or somewhere in between, you’ll walk away with real, actionable strategies to find and partner with the right jewelry manufacturer. Let’s dig in.

目次

Understanding the Chinese Jewelry Manufacturing Market

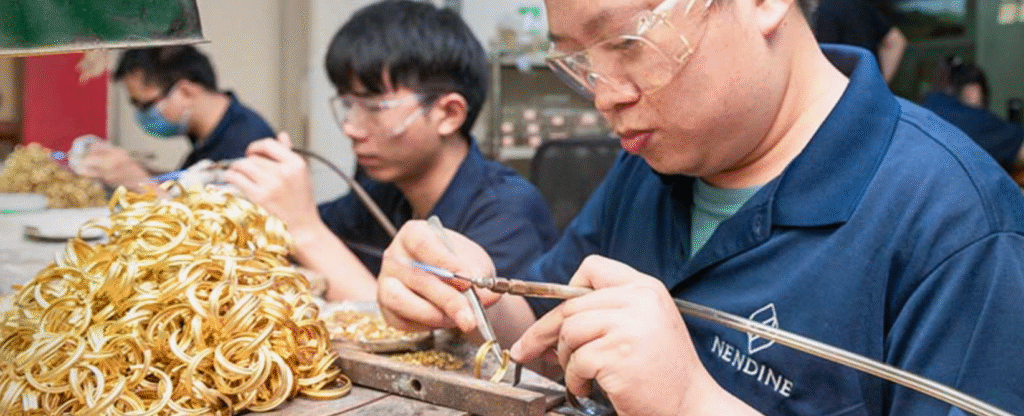

China’s jewelry industry is massive. We’re talking billions of dollars, millions of workers, and thousands of manufacturers operating at all levels—mass production, boutique crafting, and everything in between. It’s one of the biggest jewelry production hubs globally, and it caters to a variety of needs.

Some of the major manufacturing cities include:

- 深セン – Known as the Silicon Valley of hardware, it’s also a hotspot for high-end jewelry and tech-integrated pieces.

- 広州 – Ideal for fashion and costume jewelry manufacturers.

- 義烏 – Specializes in low-cost, high-volume products, perfect for trend-driven brands.

- 青島 – Known for imitation and alloy jewelry.

China’s market covers every style and category: luxury gold and diamond pieces, mid-range silver jewelry, and even fast-fashion styles made from stainless steel or resin. So no matter your niche—be it boho-inspired necklaces or minimalist sterling silver rings—you’ll find a supplier that can meet your demand.

But here’s the kicker: the sheer volume of options can be overwhelming. That’s why it’s crucial to narrow your search by understanding what region and factory specialization best match your brand goals.

Advantages of Sourcing Jewelry from China

Let’s talk about why everyone—from small Etsy sellers to multimillion-dollar e-commerce brands—flocks to China for jewelry manufacturing. The perks are plentiful, and when done right, sourcing from China can be a total game changer for your business.

1. Cost-Effectiveness

One of the biggest reasons to manufacture in China is the price. Due to lower labor costs, economies of scale, and streamlined supply chains, Chinese manufacturers can offer competitive pricing without necessarily compromising on quality. This allows you to increase your profit margins or offer more affordable pricing to your customers.

2. Wide Variety and Customization

China’s factories are incredibly versatile. Whether you need fine gold jewelry with diamond settings or budget-friendly costume pieces, there’s a manufacturer for you. Most factories also offer customization services—engraving, custom molds, plating options, and more—so you can design unique collections that stand out in a crowded market.

3. Fast Turnaround and High Scalability

Need thousands of units in a matter of weeks? Chinese manufacturers are built for speed and scale. They’re used to dealing with massive orders and can often scale production quickly without compromising on delivery timelines. This flexibility is crucial if you’re running promotions, expanding inventory, or riding the wave of a viral trend.

4. Established Infrastructure

China’s jewelry manufacturing ecosystem is mature. From raw material sourcing to assembly, plating, and quality control, many manufacturers offer one-stop solutions. That means fewer headaches for you in terms of managing logistics or finding multiple vendors for different stages of production.

5. Access to Global Markets

Many Chinese manufacturers are already well-versed in exporting products to Europe, the US, Australia, and beyond. They understand international standards, shipping procedures, and compliance requirements, making your life a lot easier.

Of course, all these advantages hinge on finding the right partner, which brings us to the next section…

Common Challenges When Dealing with Chinese Manufacturers

It’s not all roses. While there are massive upsides to sourcing from China, the road is also littered with potential pitfalls that can derail your business if you’re not prepared. Let’s look at some of the most common challenges.

1. Quality Control Issues

Not all manufacturers are created equal. Some prioritize volume over quality, leading to inconsistencies, defects, or products that don’t match your samples. If you’re not doing regular inspections, you may only find out about quality problems after the goods have landed in your warehouse.

2. Communication Barriers

English proficiency varies widely across factories. Misunderstandings about product specs, timelines, or pricing are common. If you’re not extremely clear and repetitive in your communications, you might end up with something very different than you expected.

3. Cultural Differences

Business etiquette, negotiation styles, and even the concept of deadlines can differ greatly. For example, what you see as a firm deadline might be viewed as flexible by your manufacturer. Understanding and adapting to these nuances is key to smooth collaboration.

4. Intellectual Property (IP) Risks

Let’s be real—IP theft is a legitimate concern. Without proper contracts or IP protection, your unique designs can be copied and sold to your competitors or mass-produced for other retailers. While there are ways to protect yourself (we’ll get into those later), many first-time importers overlook this critical risk.

5. Scam Manufacturers

Unfortunately, there are fraudulent companies out there posing as legitimate factories. These scammers can take your deposit and disappear or deliver low-quality goods that don’t match your agreement. Doing your due diligence is non-negotiable.

6. Long Lead Times & Delays

Between production queues, public holidays (like Chinese New Year), and global shipping backlogs, you should always prepare for delays. Having a backup plan—and extra time built into your timeline—is essential.

Overcoming these challenges starts with clarity, research, and a solid vetting process. Which brings us to…

Determining Your Specific Jewelry Needs

Before you even begin searching for a supplier, get crystal clear on what you’re actually looking for. The better you know your own needs, the easier it’ll be to filter out manufacturers who aren’t a good fit.

1. Custom vs. Ready-Made Jewelry

Are you planning to design a unique collection from scratch, or would you rather sell ready-made pieces with your branding? Custom jewelry will require a manufacturer with mold-making, CAD design, and sampling capabilities. Ready-made jewelry, on the other hand, can be sourced much faster and usually comes with lower MOQs.

2. Materials Matter

Decide what materials you want your jewelry to be made from. Here are some options:

- Gold (14k, 18k, 24k) – High-end and luxurious, but pricey.

- Silver (Sterling .925) – Great middle ground between quality and cost.

- ステンレス鋼 – Affordable, durable, and hypoallergenic.

- Brass & Copper Alloys – Common in costume jewelry.

- Resin, Acrylic, Wood, etc. – Ideal for artistic or trend-focused collections.

Different manufacturers specialize in different materials, so knowing what you need up front will save you tons of time.

3. Style and Market Positioning

Are you selling minimalistic, everyday pieces? Trendy TikTok-friendly styles? Or luxury items for a high-end boutique? Knowing your target market helps you assess whether a factory’s design style and quality level match your expectations.

4. Target Price Point

Figure out your retail and wholesale pricing models so you can reverse-engineer your ideal production cost. This will help you avoid wasting time with manufacturers whose pricing is too high (or suspiciously low).

Clarity on all these fronts will help you filter manufacturers more efficiently and set yourself up for long-term success.

How to Search for Jewelry Manufacturers in China

Alright, so now you know what you need. Time to actually find a manufacturer that ticks all the boxes. Fortunately, you have several solid avenues to explore. The key is not relying on just one channel—mix and match to cross-verify and dig deeper.

1. B2B Platforms

These online directories are the go-to starting point for most entrepreneurs. Here are the big players:

- アリババ – The king of B2B platforms. You’ll find thousands of jewelry suppliers with various certifications, reviews, and MOQs. Always filter by “Verified Suppliers” and check for Trade Assurance.

- Made-in-China.com – A serious alternative to Alibaba with a strong focus on Chinese suppliers only.

- GlobalSources.com – Slightly more curated and leans toward higher-end manufacturers.

Be cautious—these platforms also attract middlemen and drop shippers posing as factories. Always request factory videos, business licenses, and do further vetting.

2. Google Search

Surprisingly effective. Use specific keywords like:

- “custom jewelry manufacturer China”

- “OEM silver jewelry factory Shenzhen”

- “private label stainless steel jewelry supplier China”

Check their websites, look for factory photos/videos, client reviews, and whether they attend trade shows. A legitimate manufacturer will have a well-maintained site and professional communication.

3. Trade Fairs

Nothing beats face-to-face interaction. If you’re serious about building relationships, consider visiting:

- Canton Fair (Guangzhou) – Massive trade show for all industries, including jewelry.

- Hong Kong International Jewellery Show – Ideal for meeting high-quality manufacturers.

- China International Gold, Jewellery & Gem Fair – Another high-level event, often held in Shenzhen or Shanghai.

These events let you physically inspect samples, negotiate terms, and build trust.

4. Sourcing Agents and Consultants

If you’re strapped for time or don’t want to navigate the market alone, a reputable sourcing agent can help you:

- Vet factories

- Negotiate terms

- Handle shipping and quality control

Just be sure your agent is transparent and provides factory names and direct contacts.

5. Referrals and Networking

Ask in industry Facebook groups, Reddit threads, or private business communities. You’d be surprised how many people are willing to share legit supplier contacts—especially if you build a relationship or offer value in return.

Evaluating Manufacturer Profiles

Once you’ve got a list of potential suppliers, it’s time to play detective. This step is absolutely crucial if you want to avoid scams, poor communication, or inconsistent quality.

1. Company Background

Start with the basics:

- How long have they been in business?

- Do they own their factory or outsource production?

- Do they have a physical address you can verify?

- Do they specialize in the kind of jewelry you want?

A supplier who’s been around for 10+ years and has a robust export history is a good sign.

2. Certifications

Look for any of the following:

- ISO 9001 – Indicates quality management standards.

- Sedex / BSCI – For ethical and social compliance.

- RoHS / REACH – For material safety (important for EU markets).

- GIA/IGI Certifications – For gemstone authenticity (if applicable).

3. Product Range and Specialization

A factory that specializes in high-end silver jewelry is probably not the best option for cheap resin earrings—and vice versa. Ask for their latest catalog and note consistency in design, style, and materials.

4. Export History

Do they already export to your target market? If they’ve shipped to the US, UK, or EU, they’ll be familiar with regulatory compliance, quality standards, and shipping logistics.

5. Communication and Responsiveness

Do they answer emails quickly? Are they clear and professional? You’ll be communicating often, so responsiveness is key. Poor communication at this stage is a huge red flag for what lies ahead.

Once you’ve narrowed down a few promising leads, it’s time to…

Understanding the Importance of MOQ (Minimum Order Quantity)

MOQ can make or break your ability to work with a factory—especially if you’re just starting out. Here’s how to navigate it smartly.

1. What is MOQ?

MOQ is the smallest number of units a manufacturer is willing to produce in a single order. For jewelry, MOQs can range from 50 to 1000+ units per design or SKU.

MOQs are set based on:

- Material costs

- Production efficiency

- Labor requirements

- Packaging needs

2. How to Negotiate a Lower MOQ

If a supplier quotes an MOQ that’s out of your budget, here are a few tactics:

- Start with fewer designs – Focus on 1 or 2 designs and scale later.

- Offer to pay more per unit – If you’re covering their setup costs, they may accept a smaller batch.

- Use standard materials and components – Custom parts increase MOQs.

- Build a relationship – Once trust is established, suppliers are more flexible.

3. Why MOQs Matter

Don’t blindly go for the supplier with the lowest MOQ. A factory with a high MOQ might do higher-quality work because they focus on serious buyers. It’s about finding balance—not just chasing the lowest entry point.

Set your budget, understand your cash flow, and make sure you can sell through the inventory you commit to ordering. Remember, the goal is to scale gradually without drowning in unsold stock.

Verifying Legitimacy and Authenticity

This step can save you thousands of dollars and months of frustration. No matter how good a manufacturer looks on paper—or online—you should never skip due diligence. Here’s how to confirm that you’re dealing with a legitimate and capable jewelry manufacturer in China.

1. Business License Verification

Ask the supplier for their Chinese business license. Every legitimate business in China is registered and has a license issued by the State Administration for Market Regulation (SAMR). You can use third-party services like Qichacha or Tianyancha (both Chinese-language databases) to check the authenticity and:

- Registered company name

- Legal representative

- Business scope

- Establishment date

- Operational status

Tip: A red flag is if the company name on the license doesn’t match the name on their Alibaba profile or invoice.

2. Request Factory Photos or Videos

Ask for real-time photos or video tours of their manufacturing facility. Look for:

- Jewelry-making equipment

- Packaging and QC stations

- Employees actually working on production

- Factory signage showing the company name

Stock photos or unwillingness to share media is a warning sign—they could be trading companies or middlemen.

3. Use a Third-Party Verification Service

For extra peace of mind, you can hire companies to perform audits or verifications on your behalf. These services usually include:

- Business license verification

- Factory audit (onsite or virtual)

- Sample inspection

- Employee interviews

- Production capability assessment

Recommended services:

- SGS

- TÜV SÜD

- QIMA

- AsiaInspection

- Alibaba’s Onsite Check

These cost anywhere from $150–$500, but they’re worth every penny if you’re planning to make large orders.

4. Visit the Factory Yourself (If Possible)

If you’re making a serious investment and can fly to China, visiting the factory in person is the gold standard. You’ll get to:

- Inspect the production line

- Meet the team

- Negotiate face-to-face

- Build trust

If traveling isn’t an option, consider hiring a local sourcing agent or inspector to do it for you.

5. Search for Red Flags

Be wary if:

- The supplier has zero online presence outside of B2B platforms

- Their email address is a generic Gmail or Yahoo address (instead of a business domain)

- They dodge questions or become evasive during vetting

- Their prices are too low—remember, if it sounds too good to be true, it probably is

Assessing Product Quality

This is arguably the most important part of the sourcing process. You need to be obsessed with quality because your customers will be. A single batch of poorly made jewelry can kill your brand’s reputation.

1. Ask for Samples

Always request physical samples before placing a full order. Assess:

- Craftsmanship: Are joints clean and polished?

- Materials: Is it genuine silver, stainless steel, or something else?

- Finishing: Any tarnishing, sharp edges, or plating issues?

- Weight and feel: Does it feel substantial or cheap?

Don’t just rely on photos—test the samples yourself. Wear them, expose them to water, and see how they hold up over time.

2. Understand Their Quality Standards

Ask manufacturers about:

- Their internal quality control process

- How many QC staff are on their team

- What tests are done during production

- How they handle defects

A good manufacturer should have multiple QC stages, such as:

- Raw material inspection

- In-process checks

- Final inspection before packaging

3. Define Your Own Quality Criteria

You need to give them clear specs and expectations. This includes:

- Material composition (e.g., .925 silver, 316L stainless steel)

- Plating thickness (e.g., 18k gold plated, 2.5 microns)

- Tolerance for imperfections (e.g., no more than 2% defect rate)

- 梱包要件

Put all this into a Quality Checklist and make it part of your purchase agreement.

4. Consider Hiring a QC Inspector

Before your goods leave the factory, hire a third-party inspector (like QIMA or AsiaInspection) to do a final check. They’ll inspect random units from your batch and ensure everything meets your criteria.

A typical inspection report includes:

- Photos of finished products

- Measurement checks

- Defect rate analysis

- Packaging review

This extra step ensures you’re not in for a nasty surprise once your shipment arrives.

Communicating Effectively with Manufacturers

Good communication can make or break your manufacturing partnership. The clearer you are, the fewer misunderstandings, delays, and costly mistakes you’ll face.

1. Use Simple, Clear Language

Remember: even if your manufacturer claims to have “fluent English support,” they may rely on translation software or assistants. So:

- Avoid slang, idioms, or cultural references

- Use short, clear sentences

- Always confirm their understanding (ask them to repeat back)

2. Send Visual References

Don’t just describe your design—show it.

- Use sketches, 3D renders, CAD drawings, or real product photos

- Annotate images with measurements, materials, and finishes

- Create tech packs for custom designs (if possible)

Visuals remove ambiguity and reduce errors significantly.

3. Be Consistent and Professional

Use tools like:

- Email for formal communications and record keeping

- WeChat or WhatsApp for quicker chats

- Google Docs or Notion to organize product info, specs, and timelines

Keep all documentation in one place so everyone is on the same page.

4. Watch for Red Flags

If a supplier is slow to respond, vague, or inconsistent in communication, think twice before moving forward. Reliable manufacturers are professional and timely—even during busy seasons.

5. Clarify Everything in Writing

This includes:

- リードタイム

- Production timelines

- Quality standards

- 支払条件

- 梱包要件

- Return/replacement policy

Get it in writing, ideally in a formal Purchase Agreement. Trust is important—but so is protection.

Negotiating Prices and Payment Terms

Let’s be honest—negotiating with manufacturers can feel like walking a tightrope. You don’t want to insult them with a lowball offer, but you also don’t want to overpay. The trick is to know your numbers, understand the culture, and negotiate with confidence and respect.

1. Understand the Pricing Structure

Before jumping into price talks, get a clear breakdown of what’s included:

- Cost per unit

- Plating/material surcharges (e.g., for gold, silver, rhodium)

- Packaging fees

- Mold/setup fees (common for custom designs)

- Shipping costs

- Import duties (your responsibility)

Some suppliers will offer all-inclusive pricing; others will list these separately. Always ask for clarity.

2. How to Negotiate Professionally

Chinese business culture values long-term relationships over quick wins. Approach negotiations with the mindset of building a partnership. Here are some tips:

- Don’t start with price. Show serious interest, ask smart questions, and build rapport first.

- Reference competitors without threatening. You can say, “Another supplier quoted X, can you do better?”

- Offer something in return. For example, promise a second order or higher quantity later if they lower the MOQ or price now.

- Negotiate around other terms if price is fixed. Ask for:

- Faster lead times

- Free packaging upgrades

- Flexible payment terms

3. Payment Methods and Safety Tips

Standard payment methods include:

- T/T (Telegraphic Transfer): Most common. Usually 30% deposit, 70% before shipment.

- PayPal: Good for small orders but comes with high fees.

- Alibaba Trade Assurance: Offers buyer protection for payments.

- Letter of Credit (L/C): More secure, but usually for large orders.

- Western Union: Avoid—high risk, little protection.

Tips to stay safe:

- Never send money to a personal bank account

- Use contracts and formal invoices (called a Proforma Invoice)

- Break payments into milestones for large orders

4. Watch Out for Hidden Costs

Make sure your quote includes everything—plating, engraving, QC, packaging, and shipping. If the price seems too good to be true, it probably is. Low-cost manufacturers may cut corners on materials or skip quality checks.

Protecting Your Intellectual Property

When working with overseas manufacturers, protecting your designs and brand becomes even more critical. China has a reputation for IP risks, but there are proactive steps you can take.

1. Use NDAs (Non-Disclosure Agreements)

Before you share any custom designs or confidential info, have the manufacturer sign a bilingual NDA (in English and Chinese). Make sure the Chinese version is legally binding in China.

You can also include:

- Non-compete clauses

- Penalties for violations

- Agreement on confidentiality for subcontractors

2. Get a Manufacturing Agreement in Place

An NDA alone isn’t enough. Draft a manufacturing agreement that outlines:

- IP ownership

- Sample approval process

- Lead times and penalties

- Quality standards

- 支払条件

- Dispute resolution method

Use a lawyer or template tailored to China’s legal system—this document is your main line of defense.

3. Register Your IP in China

Here’s a hard truth: IP protection in your home country doesn’t cover you in China. You must register:

- Your brand name/trademark with the China National Intellectual Property Administration (CNIPA)

- Your design patent if applicable

This is especially important if you plan to scale. Once you register, you gain legal grounds to stop copycats or unauthorized use.

4. Limit Exposure

You can also reduce risk by:

- Working with trusted manufacturers who don’t outsource

- Dividing production (e.g., parts made by separate vendors)

- Keeping proprietary elements (like packaging design or engraving) in-house

Shipping and Logistics

You’ve found your manufacturer, finalized the order, and production is complete—now what? It’s time to get those beautiful pieces from China to your doorstep. But international shipping can be a beast if you don’t understand the basics.

1. Common Shipping Terms

- FOB (Free On Board): Supplier handles delivery to the port. You handle ocean freight, insurance, and customs.

- CIF (Cost, Insurance, and Freight): Supplier covers shipping to your port.

- EXW (Ex Works): You’re responsible for the entire shipping process—pickup from the factory, freight, and clearance.

For beginners, FOB or CIF are the easiest to manage.

2. Choosing the Right Shipping Method

- 航空貨物: Fast (3–7 days), but expensive. Ideal for urgent or lightweight orders.

- Sea Freight: Affordable, but slower (25–40 days). Best for bulk orders.

- Express Courier (DHL, FedEx, UPS): Fast, reliable, and best for small orders or samples.

3. Work with a Freight Forwarder

Freight forwarders handle:

- Booking cargo

- Preparing documentation

- Customs clearance

- Delivering to your warehouse

A good freight forwarder is worth their weight in gold. Ask your manufacturer for recommendations or find one with jewelry shipping experience.

4. Be Prepared for Customs

You’ll need:

- Commercial Invoice

- Packing List

- Bill of Lading or Airway Bill

- HS Code for Jewelry (e.g., 7117.19 for costume jewelry)

Know your country’s import duties and VAT requirements. Some importers get caught off guard by surprise taxes—do your homework or consult a customs broker.

Building Long-Term Relationships with Manufacturers

Once you’ve found a good supplier, don’t treat them as just a vendor—treat them as a partner. Strong relationships can lead to better pricing, faster lead times, and priority service.

1. Communicate Regularly

Keep them in the loop about your product launches, marketing plans, and reorder schedules. It shows you’re serious and helps them plan capacity.

2. Be Reliable

Pay on time, be respectful, and don’t ghost them after one order. Manufacturers value consistency and will prioritize clients who behave professionally.

3. Visit or Send Gifts

A little goodwill goes a long way in Chinese business culture. Consider visiting annually (if possible), or send New Year gifts. These small gestures can cement trust.

4. Provide Feedback

Whether good or bad, your feedback helps improve quality and efficiency. Don’t just complain—offer suggestions, and be constructive.

5. Think Long-Term

Want lower prices? Better terms? More flexibility? Build a relationship that shows you’re here for the long haul—not just a one-time order.

結論

Finding a reliable jewelry manufacturer in China may seem daunting at first, but with the right approach, it’s absolutely achievable—and incredibly rewarding. Start by understanding your own needs. Research the market, vet your suppliers thoroughly, and build relationships, not just transactions.

The right manufacturer isn’t just someone who makes your product. They’re a partner who can help you scale your brand, improve your margins, and bring your creative vision to life.

Take the time to do it right, and your jewelry business will shine brighter than ever.

FAQs About How to Find a Reliable Jewelry Manufacturer in China

1. What is the average lead time for custom jewelry production in China?

Lead times can vary, but typically range from 15–45 days, depending on the complexity of the design, material availability, and factory capacity.

2. Can I trust jewelry suppliers I find on Alibaba?

Yes, but with caution. Always verify their business license, ask for references, and use Trade Assurance to protect your payment.

3. How do I handle disputes with Chinese manufacturers?

Try resolving it through clear communication first. If that fails, refer to your written agreement. Platforms like Alibaba and sourcing agents can help mediate.

4. What certifications should a jewelry manufacturer have?

Look for ISO 9001, Sedex/BSCI (ethical practices), RoHS (material safety), and specific gemstone or metal certifications depending on your product.

5. Is it better to use a sourcing agent?

If you’re new to importing or don’t speak Chinese, yes. A good agent can save you time, avoid scams, and manage quality control—just make sure they’re transparent.